Mass customization

Reduce costs and time to market for mass-customized products with nTop's advanced design for additive manufacturing (AM) capabilities.

Benefits of mass customization with AM

Mass customization with AM offers a range of benefits across different industries, from improved patient outcomes to safer sports equipment.

Download the personalized medical devices guide

Learn how mass customization for medical devices can be leveraged to reap many rewards for patients and medical practitioners.

Industry applications of mass customization

Mass customization with additive manufacturing helps create higher quality, cost-effective products across a variety of industries.

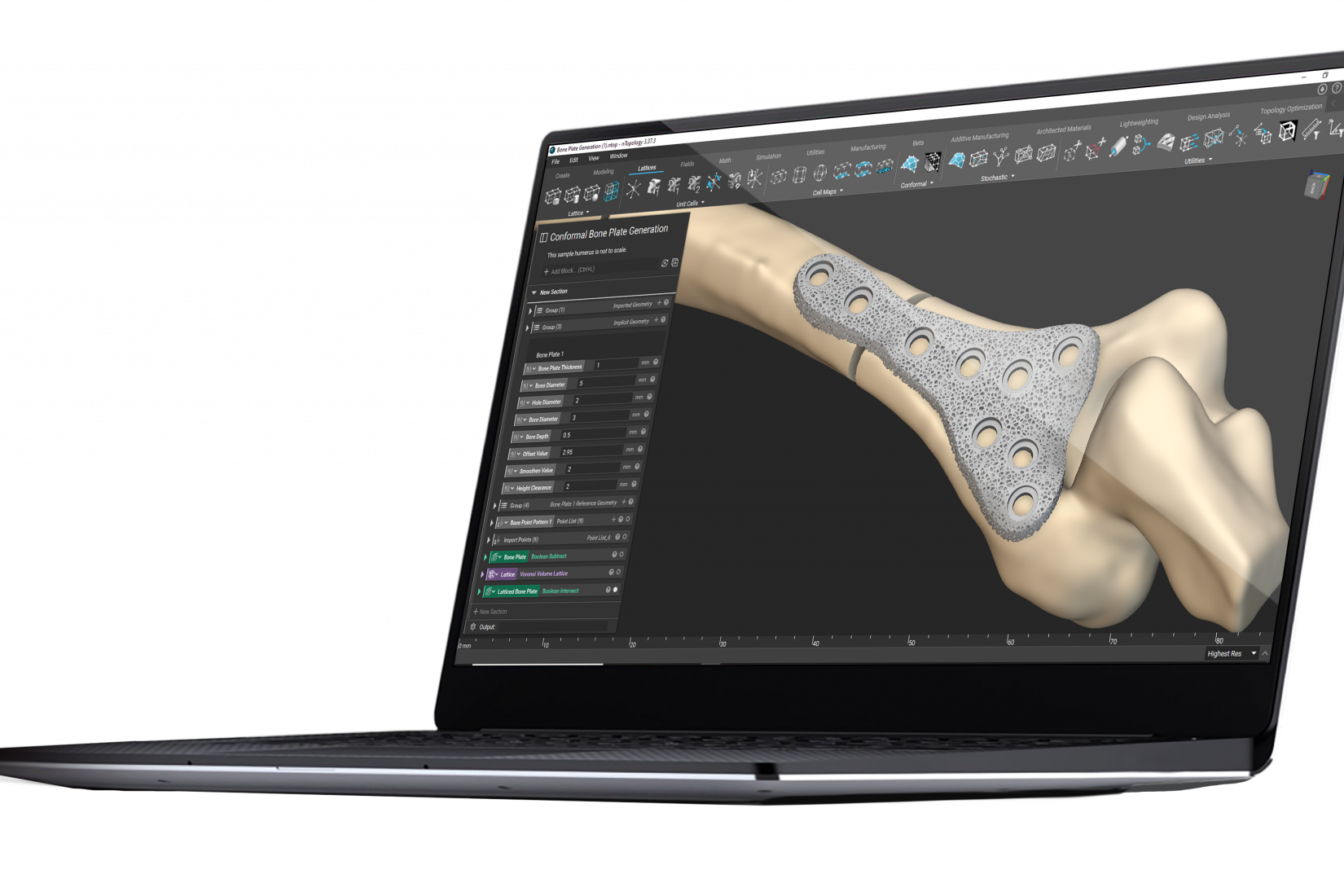

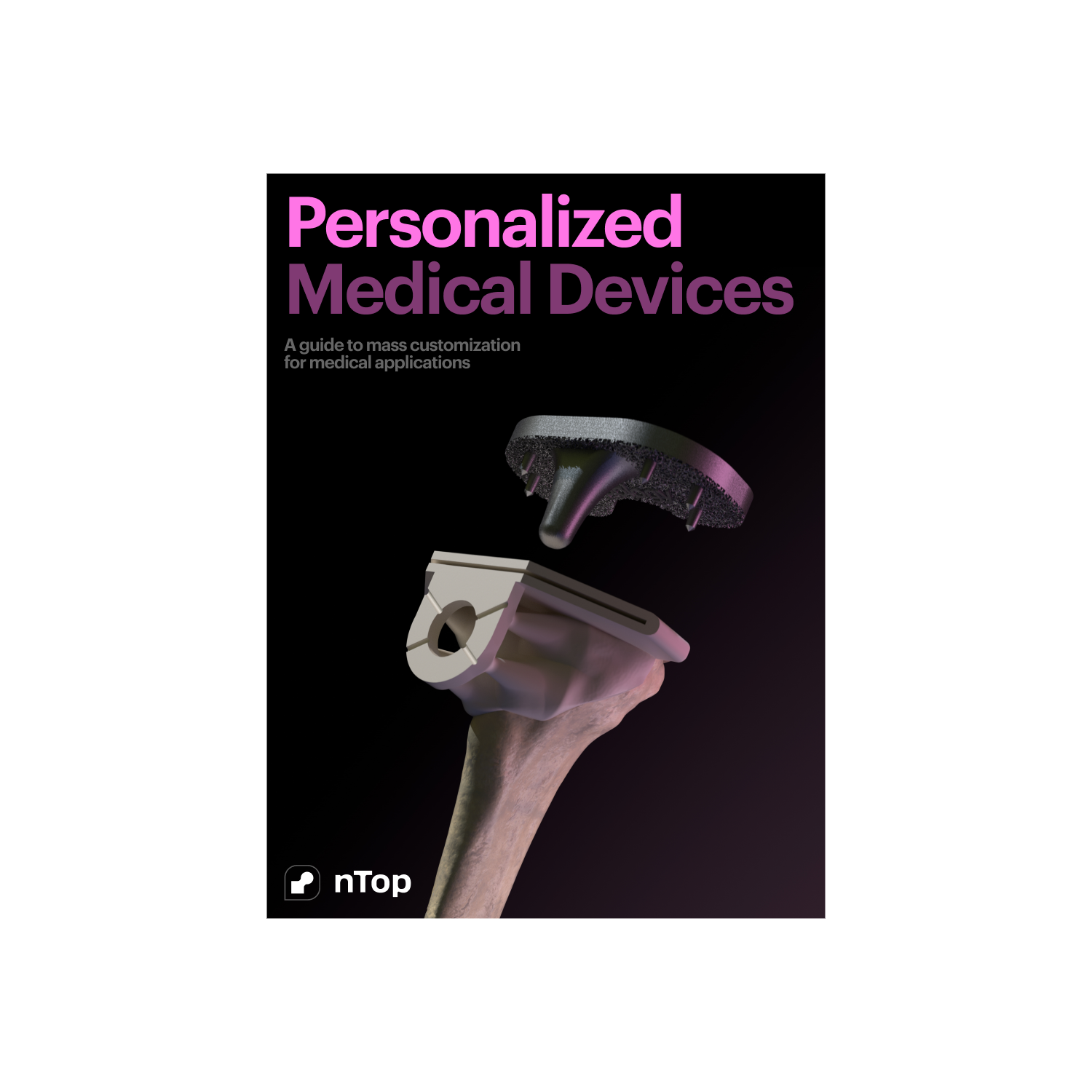

Medical device industry

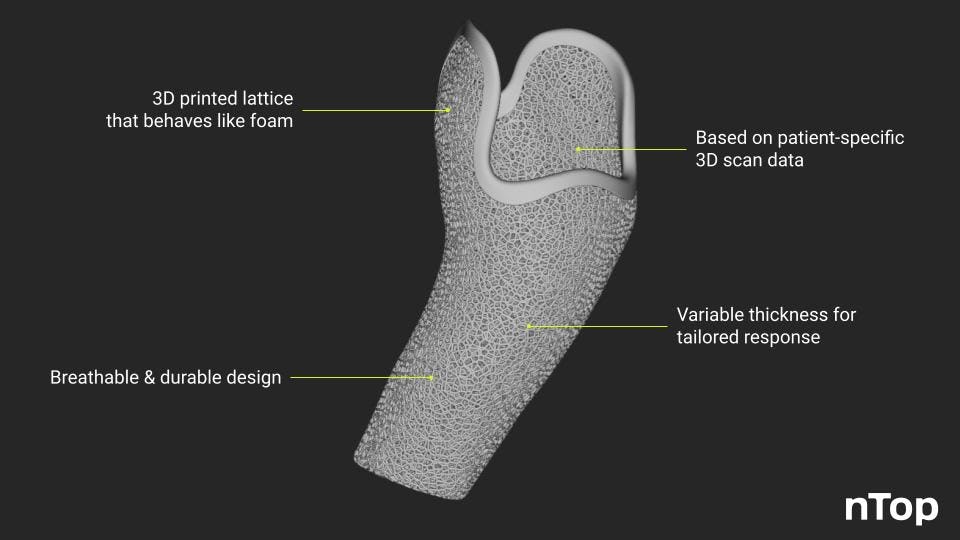

Mass customization with AM is helping engineers create patient-specific medical devices, like prosthetics and orthotics, that improve patient outcomes.

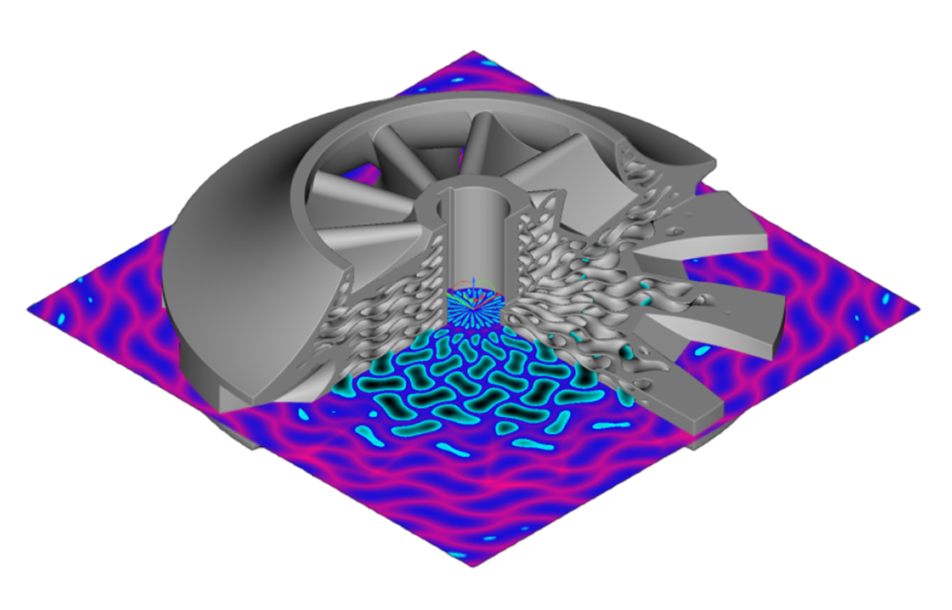

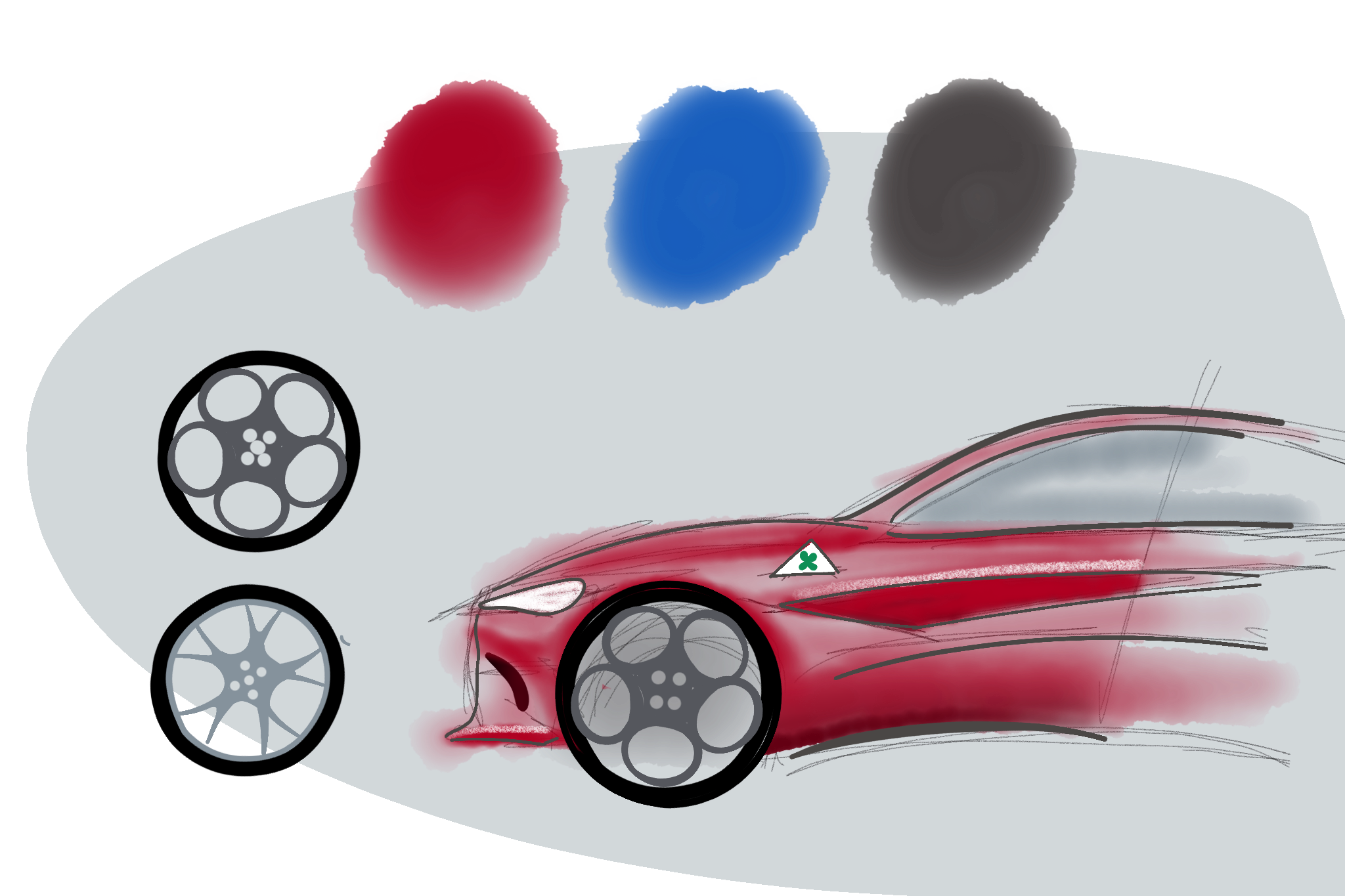

Automotive industry

Additive manufacturing paired with mass customization allows engineers to introduce texturing, text, and foams into their automotive designs to improve the aesthetics of custom accessories and interior and exterior vehicle features.

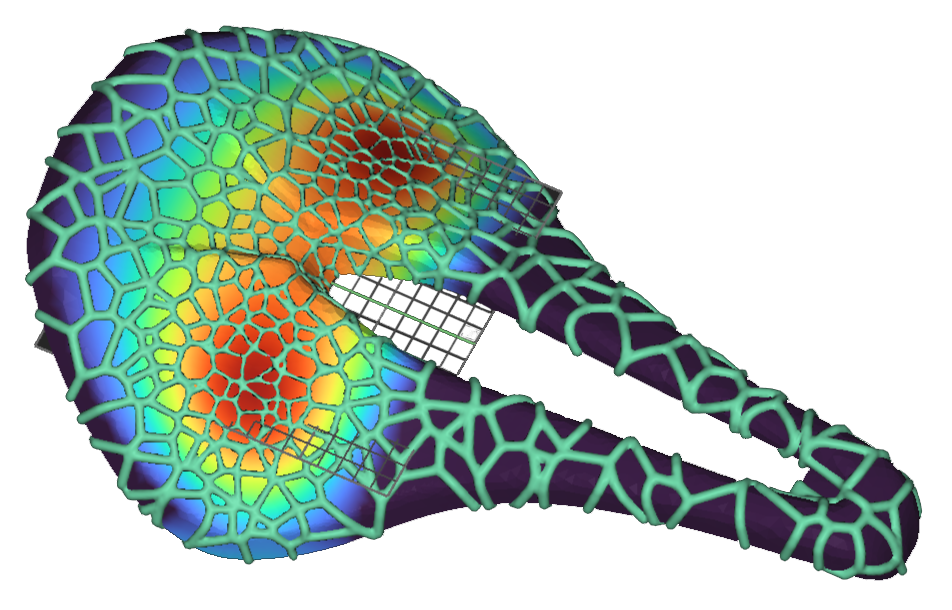

Consumer products industry

Mass customization with 3D printing empowers engineers to create one-of-a-kind consumer products, like custom footwear and sports equipment, to improve ergonomics and user comfort.

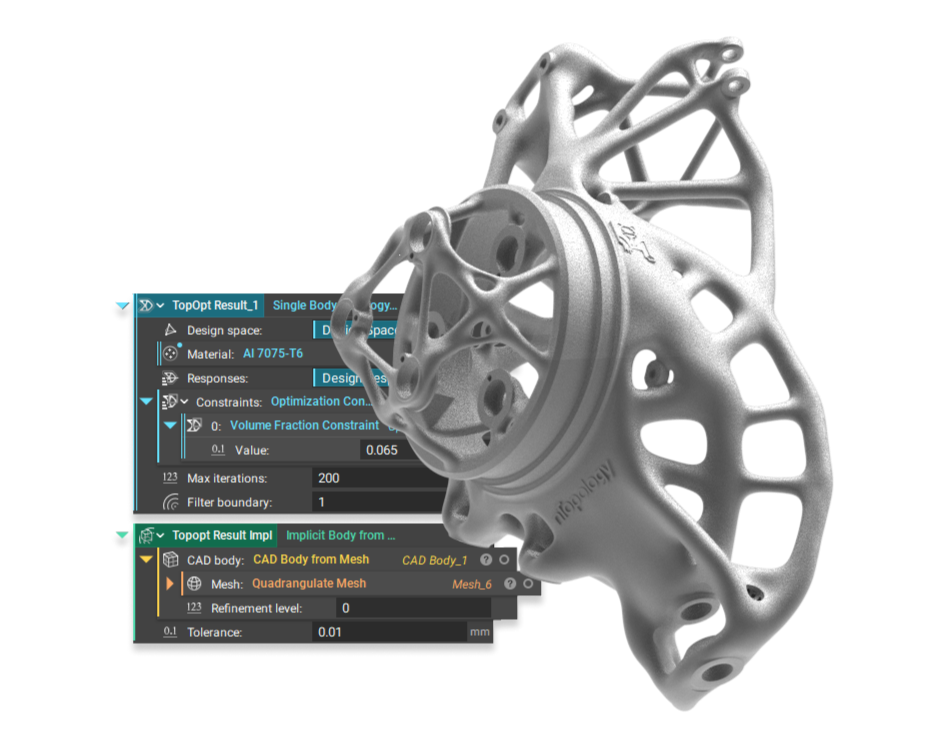

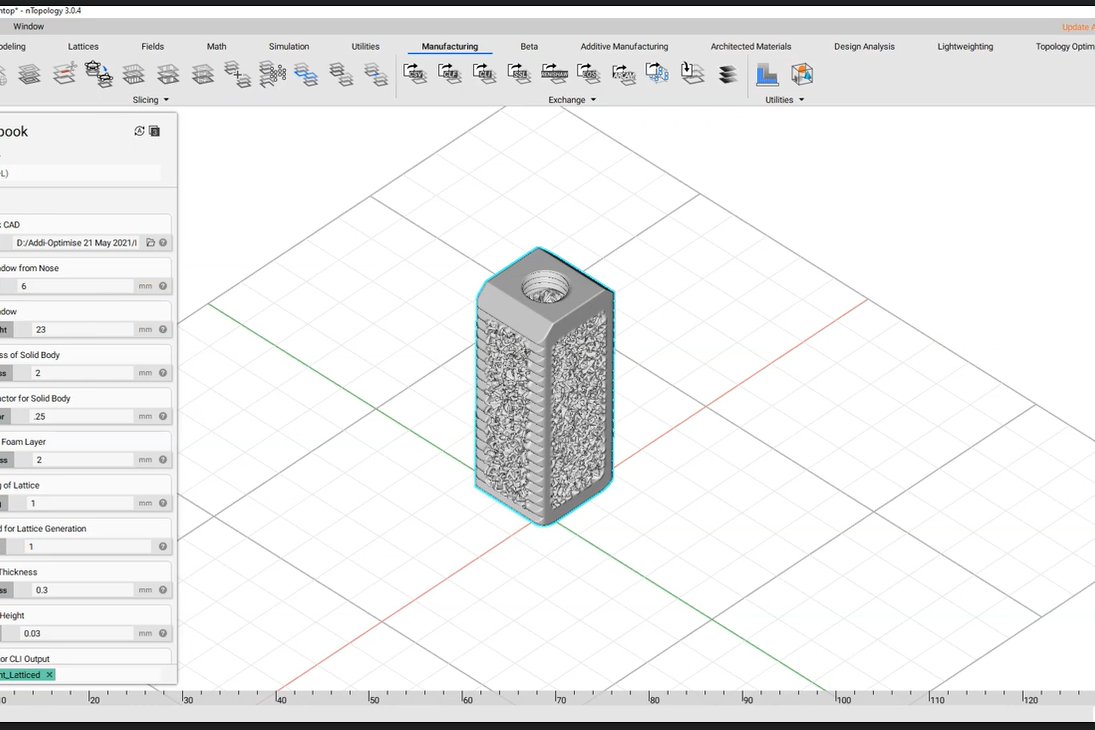

nTop’s critical tools for mass customization with additive manufacturing

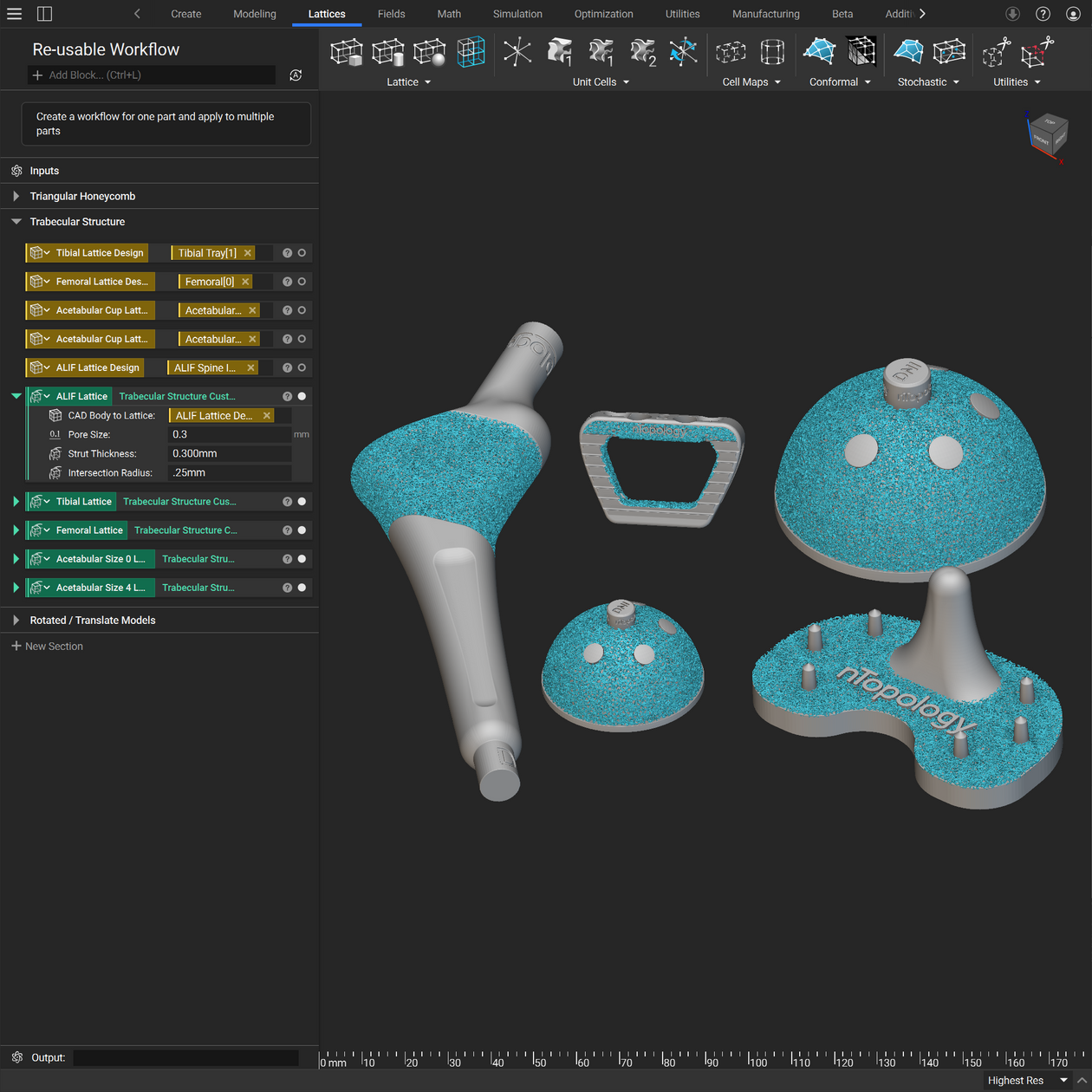

Reusable workflows

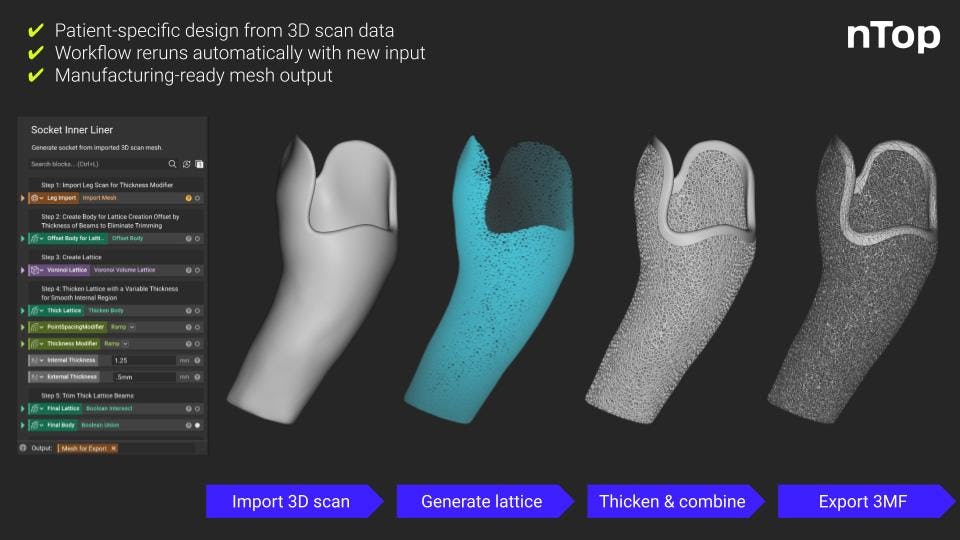

Design processes, not just parts. Once you have built your workflow, you can rerun it with new inputs repeatedly and accurately.

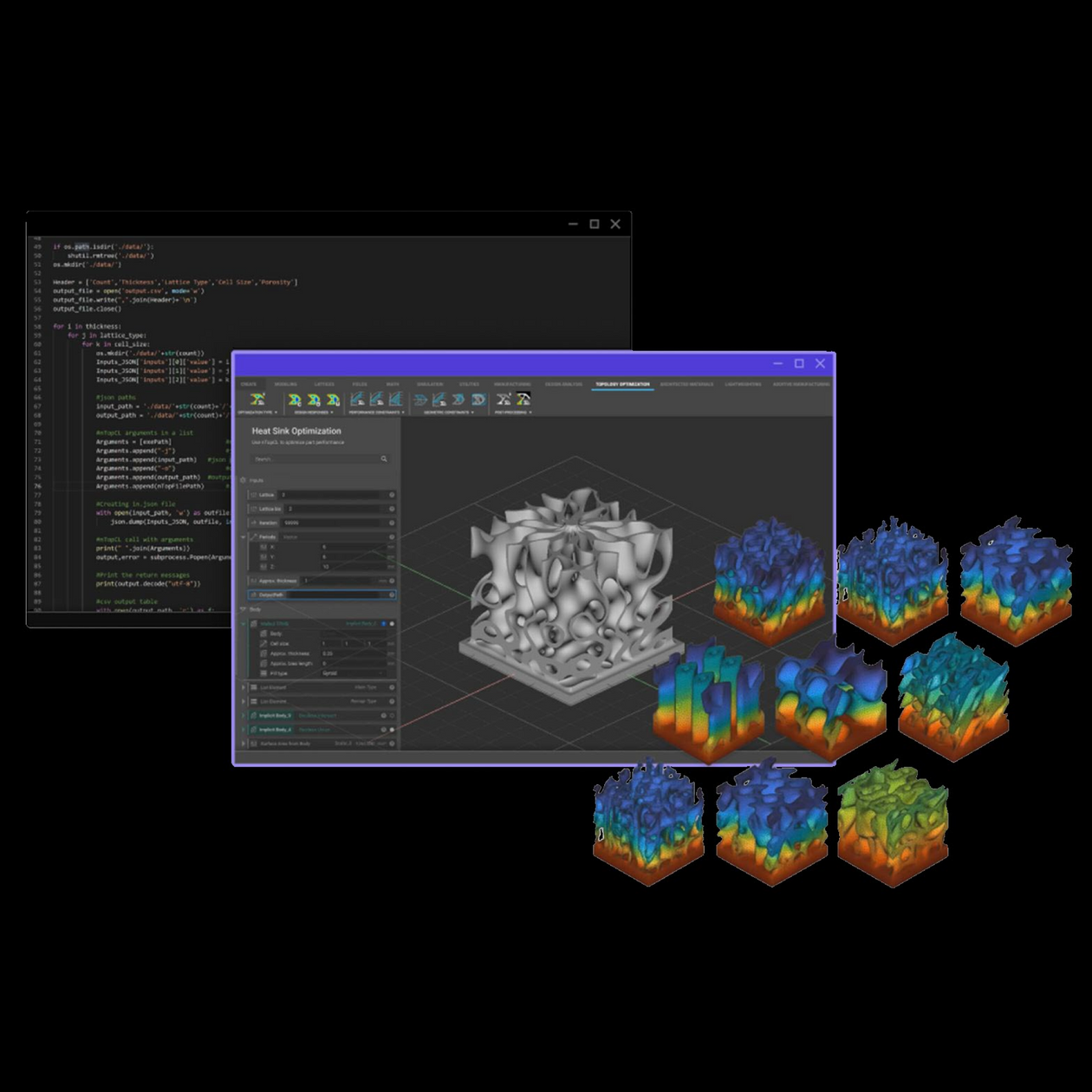

nTop Automate

Run nTop files through a programmatic environment with different input variables for rapid custom design generation.

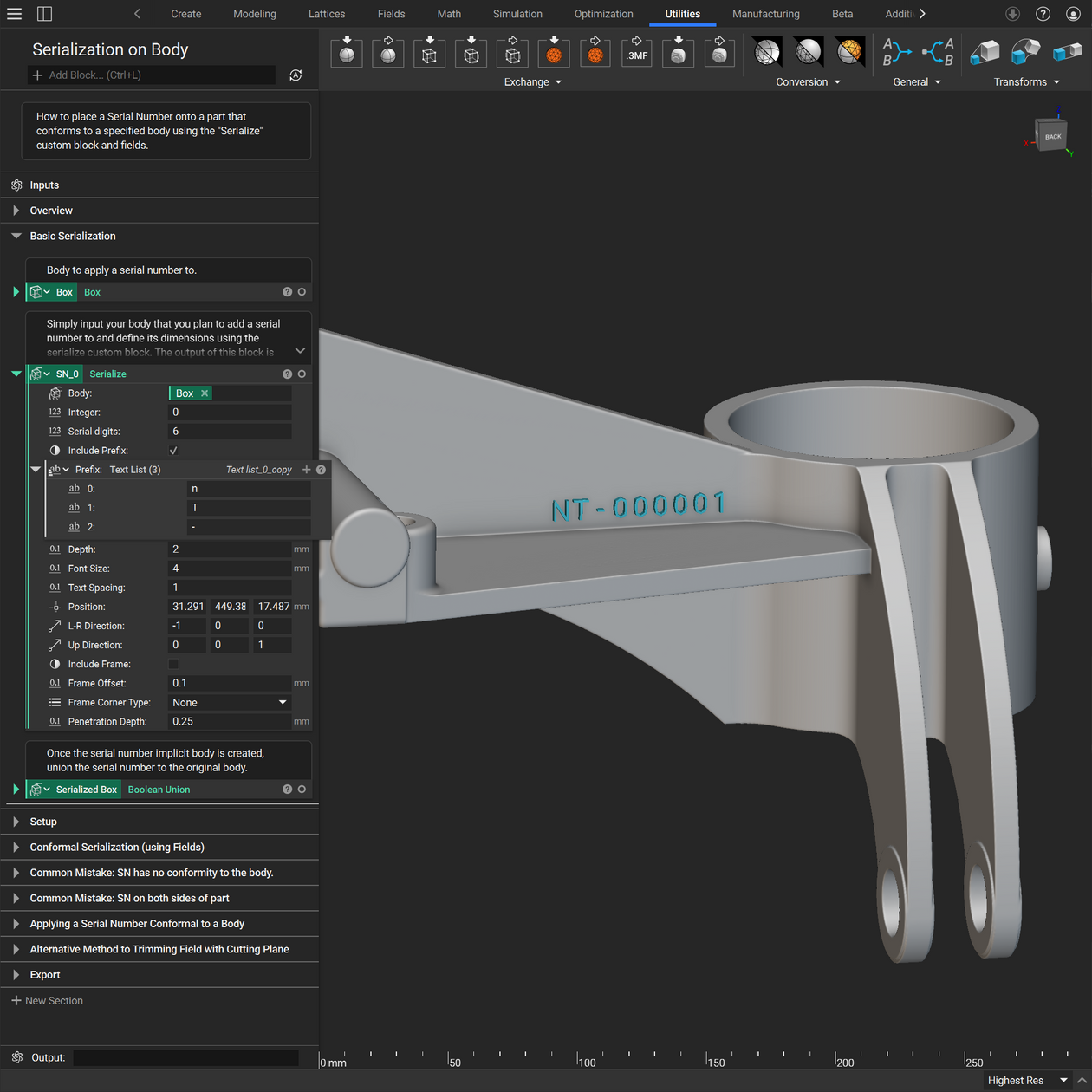

Label and logo automation

Effortlessly swap labels and logos. Add serial numbers and other identifying product markings without ever causing errors.

User-specific geometry

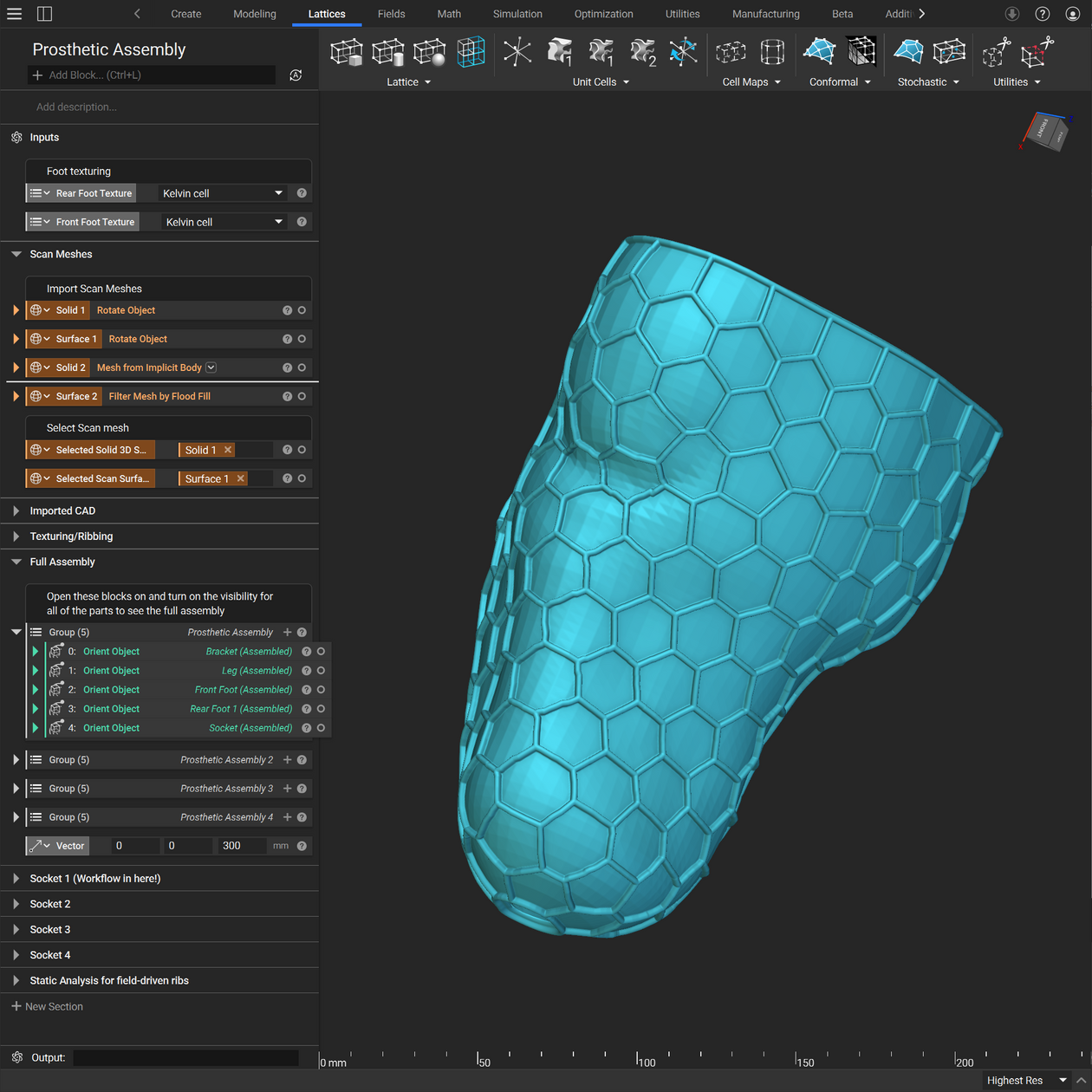

Import 3D scan data into reusable workflows to quickly create products tailored to individuals.

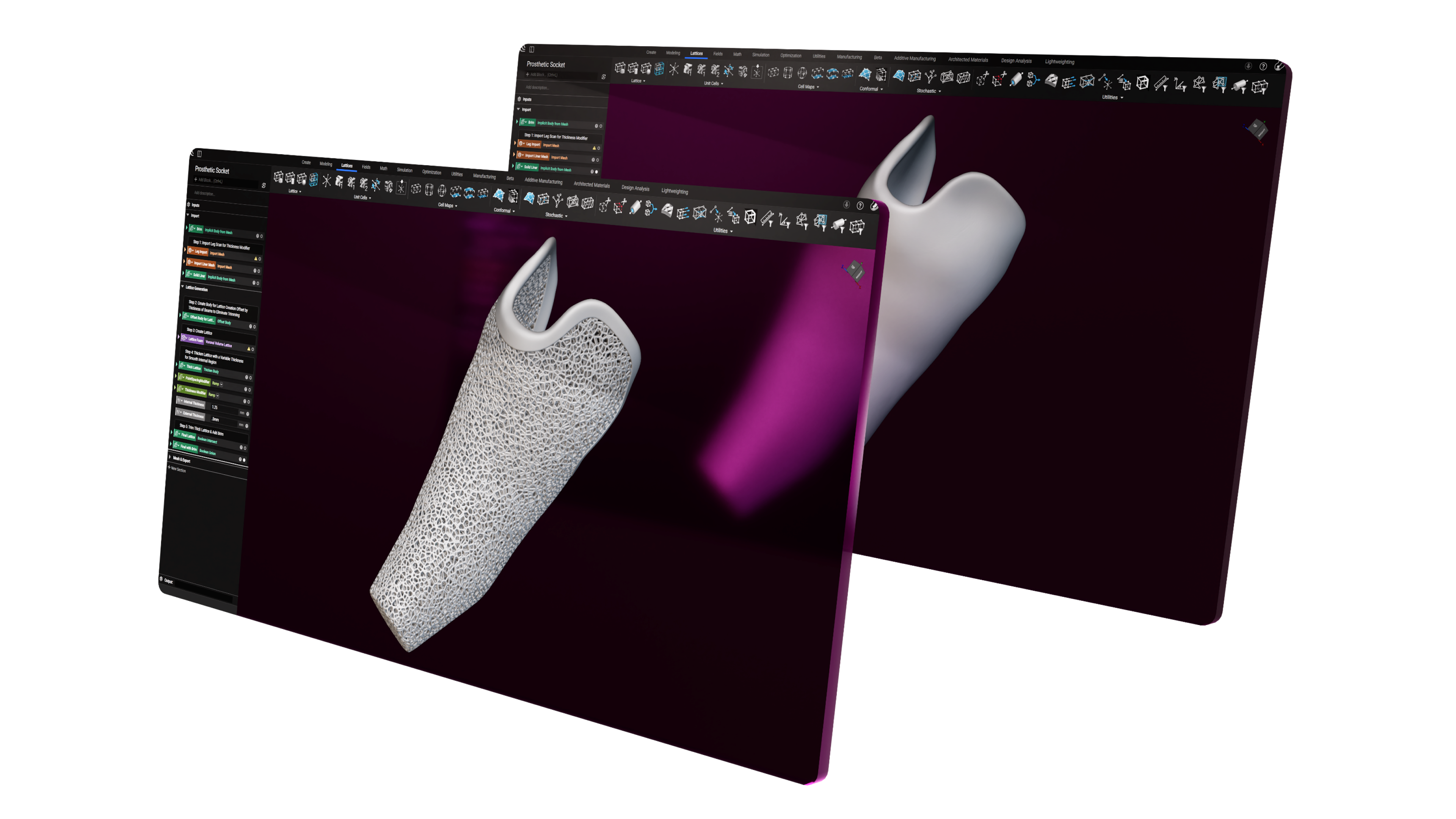

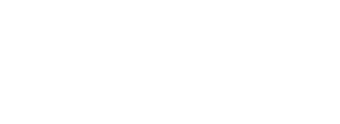

Latticing, digital workflows, and mass customization bring the world’s most advanced prosthetics to the jungles of Guatemala

LifeNabled volunteers used 3D patient scan data to automatically generate prosthetic sockets in nTop. The new digital workflow saves more than three days of work, and it can be replicated anywhere in the world. The resulting prostheses are more breathable, flexible, and comfortable for the patients they serve in Guatemala.

Software built on transformative technology

Mass customization resources for engineers and designers

Get started with mass customization.

nTop has the tools you need to maximize the benefits of AM.