3D printed fixtures for CMM inspection with the FDM Fixture Generator

Written by Chase Allan | Associate Product Manager at nTop

Published on September 23, 2021

The new CMM Fixturing Module of the FDM™ Fixture Generator streamlines fixture design for inspection in Coordinate Measuring Machines. The tool enables QA engineers and technicians to generate & 3D print custom fixtures with just a couple clicks.

Applications

Key Software Capabilities

- Design automation

Automating repetitive design processes and workflows is one nTop’s core benefits. The ongoing collaboration between nTop and Stratasys is providing automated workflows for custom jigging and fixturing operations.

Generating conformal assembly, welding, or CMM fixtures has never been as streamlined or automated as it is now with nTop's design software. The three modules of the FDM™ Fixture Generator make filament-based additive manufacturing (and other 3D printing technologies) more accessible on the shop floor. They drastically reduce the time needed to perform non-value-added tasks.

Watch the video to see the CMM module of the FDM™ Fixture Generator in action:

nTop CMM Module video

The CMM Fixturing Module

Inspecting parts for aerospace, automotive, electronics, industrial, or medical applications demand precise and secure part positioning. However, fastening irregular or complex geometries with off-the-shelf clamps poses many practical challenges. 3D printed jigs and fixtures can help overcome this problem, but manually designing them is time-consuming.

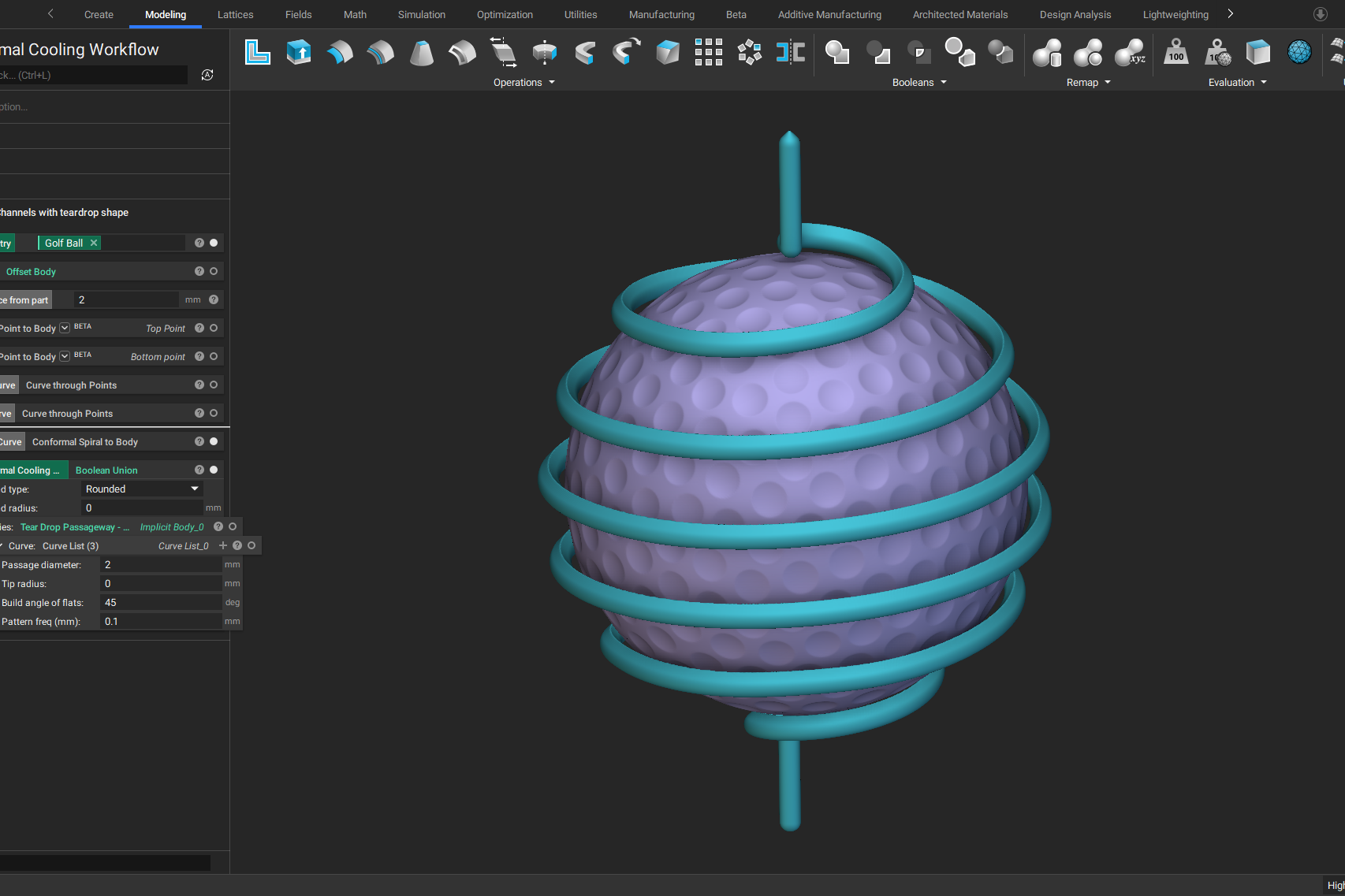

In the latest FDM™ Fixture Generator module, the nTop team applied the software’s generative design and automation capabilities to automatically design fixtures for CMM applications.

With a few quick clicks, you can import the part and the CMM attachment plate and define the holding locations. Within a few seconds, nTop generates conformal fixtures to securely fasten the piece to the CMM plate. The fixture design is ready to be 3D printed without the need for support structures.

Automatically generated 3D printed fixtures for CMM inspection on Aerospace component

Why use the CMM Module?

nTop’s reusable workflow capabilities make it different from traditional CAD tools commonly used for fixture design. nTop automatically generates a fixture to hold new part geometry quickly and with minimal user interaction.

Simply put, nTop streamlines fixture generation and makes it accessible even to users without CAD experience. There is no need to start from scratch when the design changes or when inspecting a new part.

The software’s computational design backend enables you to generate fixtures for any part geometry (whether imported as a CAD file or a mesh), in any orientation and with any number of contact points.

Additionally, users can change other important parameters without significantly increasing the rebuild time. Early beta users are also exploring this technology to enable mass customization of fixtures — regardless of quantity or model complexity.

The 3D printed fixtures conform to the geometry of the inspected part and were generated with a couple of clicks.

Leading manufacturing companies have already adopted the previous modules of the FDM™ Fixture Generator. For example, the Masking Module is used in shop floors worldwide to generate protective fixtures for finishing and post-processing.

Watch the video to see the Masking Module of the FDM Fixture Generator in action:

nTop Masking Module video

Ready for the next step?

Turn-key software solutions — like the FDM Fixture Generator — unlock more value for users of advanced manufacturing technologies, such as FDM 3D printing. They also expedite design time in applications like CMM inspection and ultimately reduce bottlenecks in the manufacturing space.

If you are interested in seeing an in-depth demonstration of the fixturing modules, or you would like to test them out for yourself, please contact us.

Chase Allan

Associate Product Manager at nTop

Related content

- VIDEO

Creating a computational design workflow to lightweight drone panels with nTop’s new ribbing tools

- VIDEO

nTop Siemens Energy at CDFAM NYC 2024

- CASE STUDY

How blueflite reduced fuselage mass 25% in 4 hours instead of 4 weeks

- GUIDE

Download: Advanced design software and additive manufacturing for personalized implants

- ARTICLE

Optimizing thermal management with conformal cooling to extend operational life