LifeNabled created a reusable digital workflow to 3D print prosthetics

See how LifeNabled used nTop’s reusable workflows and topology optimization to produce custom 3D-printed prosthetic sockets with flexible inner liners.

Key Software Capabilities

- Lattice structures

- Design automation

- Topology optimization

Summary

With nTop’s reusable workflows and topology optimization capabilities, LifeNabled created a fully digital workflow to produce custom 3D-printed prosthetic sockets with flexible inner liners. Now, 35 patients in the jungle of Guatemala are walking on the most advanced prosthetic and orthotic devices in the world.

About: Brent Wright is a Certified Prosthetist and Orthotist. He and his wife Meredith co-founded LifeNabled, a non-profit provider of prosthetic solutions for the developing world.

- Industry: Medical devices

- Size: 1-100 employees

- Location: Raleigh, North Carolina, USA

- Product: Custom 3D-printed prosthetic sockets with flexible inner liners

The project

Creating custom 3D-printed sockets

Hospital Shalom is the only facility that provides prosthetics care to patients of the Petén region in northern Guatemala.

LifeNabled hosts biannual clinics in northern Guatemala where they have treated hundreds of patients who would otherwise be unable to access prosthetic care.

Unfortunately, the traditional fabrication of prostheses took a physical toll on Wright’s team. To minimize labor and improve efficiency, LifeNabled decided to develop a digital workflow and create custom, 3D-printed prosthetic sockets based on patient data.

The challenge

Automating and streamlining design

Manual fabrication of prostheses is a time-consuming, expertise-intensive, and laborious process.

To ensure their prostheses were comfortable, breathable, and cost-effective to make, LifeNabled needed advanced topology optimization capabilities. The team also had to find a way to rapidly apply their chosen design parameters to 30+ custom socket designs. To achieve this, they had to leverage intelligent design automation features.

nTop was the only design software that offered all the features necessary for LifeNabled to meet its design objectives and conquer these challenges.

The solution

Next-generation design software

With the help of nTop’s advanced capabilities, the team created a fully digital process that saved time, improved fit, and reduced manual labor. They implemented a semi-automated workflow and replaced the traditional inner liners with 3D-printed foams for flexibility and comfort.

The results

2-3 days saved

during fabrication

More than 1 day saved

during the design phase

35 amputees evaluated

in 2 days, thanks to the speed of 3D scanning

Why nTop?

To digitize the traditional fabrication process, facilitate rapid customization, and introduce advanced topology into their prostheses, the team needed a powerful tool. Without nTop, it would not have been possible for LifeNabled to create these advanced prosthetics.

Reusable workflows

With nTop’s reusable design processes, LIfeNabled’s team automated repetitive design tasks. This made customization quicker and saved more than a day of error-prone computational processing during the design phase.

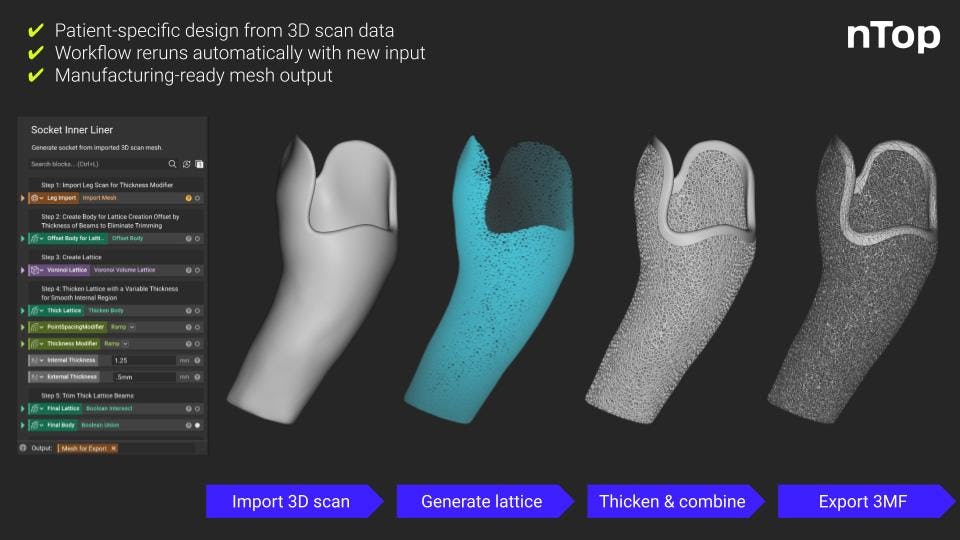

Overview of the design process in nTop — from importing a 3D scan mesh to exporting a manufacturing-ready 3MF mesh file

3D scan data

LifeNabled used 3D scanning to create custom devices at scale. They took a 3D scan of each patient, then brought that patient-specific data into the reusable design process for a tailored fit on each device.

Digital fabrication of prostheses is streamlined. First, a 3D scan of the patient is taken (left) and then the custom socket and inner lining can be 3D printed from a digital design (right).

Topology optimization

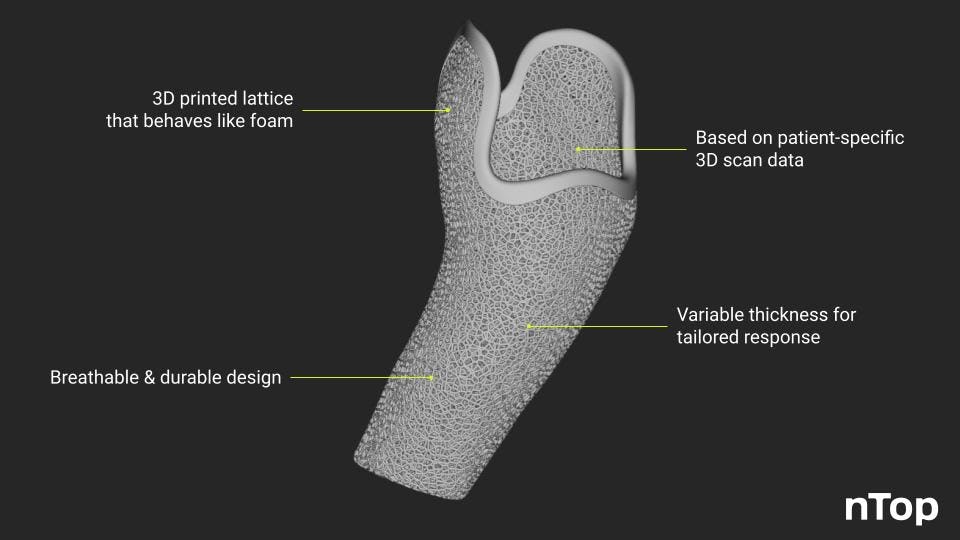

LifeNabled transformed the essential inner liners of the prostheses by designing flexible lattice structures with custom properties that imitate the properties of traditional foams while eliminating the need for the usual costly, uncomfortable gel-like liners typically used.

The final design of one of the 30+ custom-made flexible inner linings designed in nTop.

Lightning-fast lattice generation

nTop’s advanced engineering design software allowed LifeNabled to rapidly generate lattices with closely controlled design input parameters, such as beam thickness and porosity, to create flexible inner socket liners that were tuned to the physiology and preferences of the patient.

Three of the 30+ patients fitted with their new 3D printed prosthetic devices.

Conclusion

Thanks to nTop in combination with digital manufacturing, LifeNabled took an important step toward their goal of creating a global network of prosthetic device providers for the developing world.

Related content

- VIDEO

nTop 2025 Nvidia GTC Presentation

- VIDEO

When your design changes, how fast can you respond?

- CASE STUDY

Replacing spacecraft supermaterial with high-performance lattice

- VIDEO

Creating a computational design workflow to lightweight drone panels with nTop’s new ribbing tools

- WEBINAR

Accelerating Product Engineering with Computational Design