Automated Design of 3D Printed Molded Fiber Pulp Tooling

video: Automated Design of 3D Printed Molded Fiber Pulp Tooling

Published on May 28, 2021

Fiber molded pulp is a widely used sustainable packaging material made out of recycled paper. 3D printed molds can unlock many advantages for molded pulp manufacturers — time and cost savings, easy customization, more streamlined operations, and so on.

In this nTop Live, John Graham, Director of Application Engineering, shows examples of automated design processes that can instantly generate 3D printed tooling for fiber pulp molding. He shares workflows that enable you to build and reuse configurable design processes to develop optimal tools with little effort.

Watch and learn how to:

- Build automated and reusable processes to design fiber pulp mold tooling

- Generate offset faces, holes, supports, and other essential mold features

- Get more out of your investment in advanced 3D printing technologies

Related content

- VIDEO

Creating a computational design workflow to lightweight drone panels with nTop’s new ribbing tools

- VIDEO

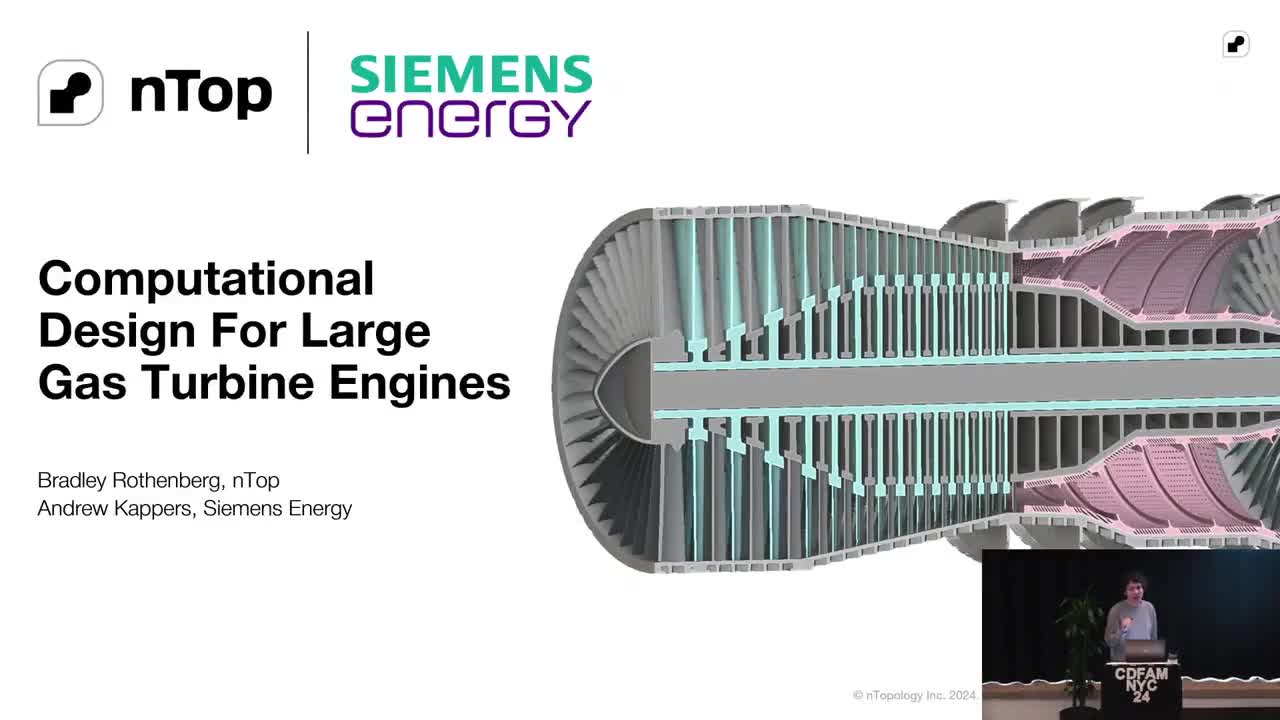

nTop Siemens Energy at CDFAM NYC 2024

- ARTICLE

An nTop intern’s experience: Learning computational design and creating a lightweight drone

- VIDEO

Thermal Applications - The Hot Topics

- VIDEO

Design better implants for osseointegration with the Lattice Pore Size Block