Streamlining manufacturing for medical implants, with Renishaw and IMR

video: Streamlining manufacturing for medical implants, with Renishaw and IMR

Published on January 8, 2020

In this case study, we will explore how nTop has partnered with Renishaw and Irish Manufacturing Research to design and develop an orthopedic spinal implant. With the workflow capabilities provided by nTop, IMR was able to leverage multiple design iterations and provide a viable manufacturing output for Renishaw to produce via their RenAM 500M machine.

With nTop’s extensive lattice beam control, the product development team at IMR was able to explore their design space before settling on a customized lattice concept. Through high-speed iteration and workflow reusability, IMR was able to achieve a high performing medical device in drastically reduced times.

Watch this session to see how nTop can serve as a digital design solution to make better medical devices in the world of advanced manufacturing.

Related content

- VIDEO

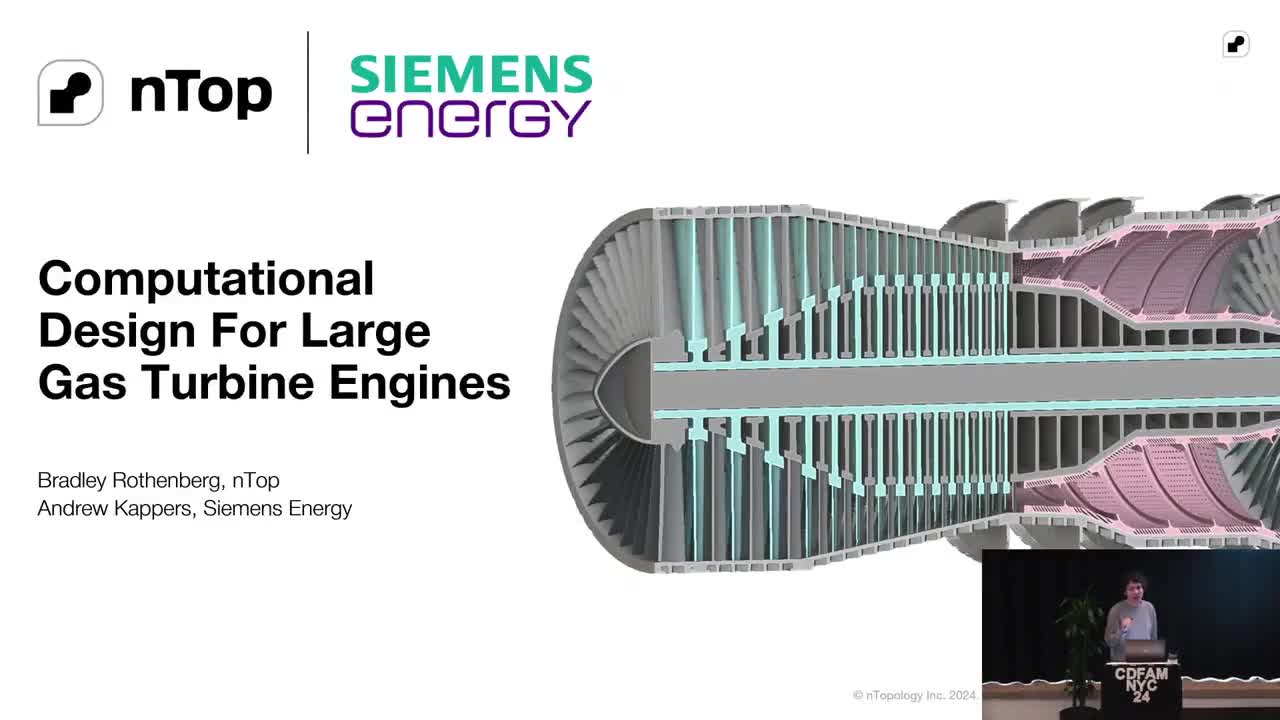

nTop Siemens Energy at CDFAM NYC 2024

- VIDEO

Thermal Applications - The Hot Topics

- VIDEO

Design better implants for osseointegration with the Lattice Pore Size Block

- VIDEO

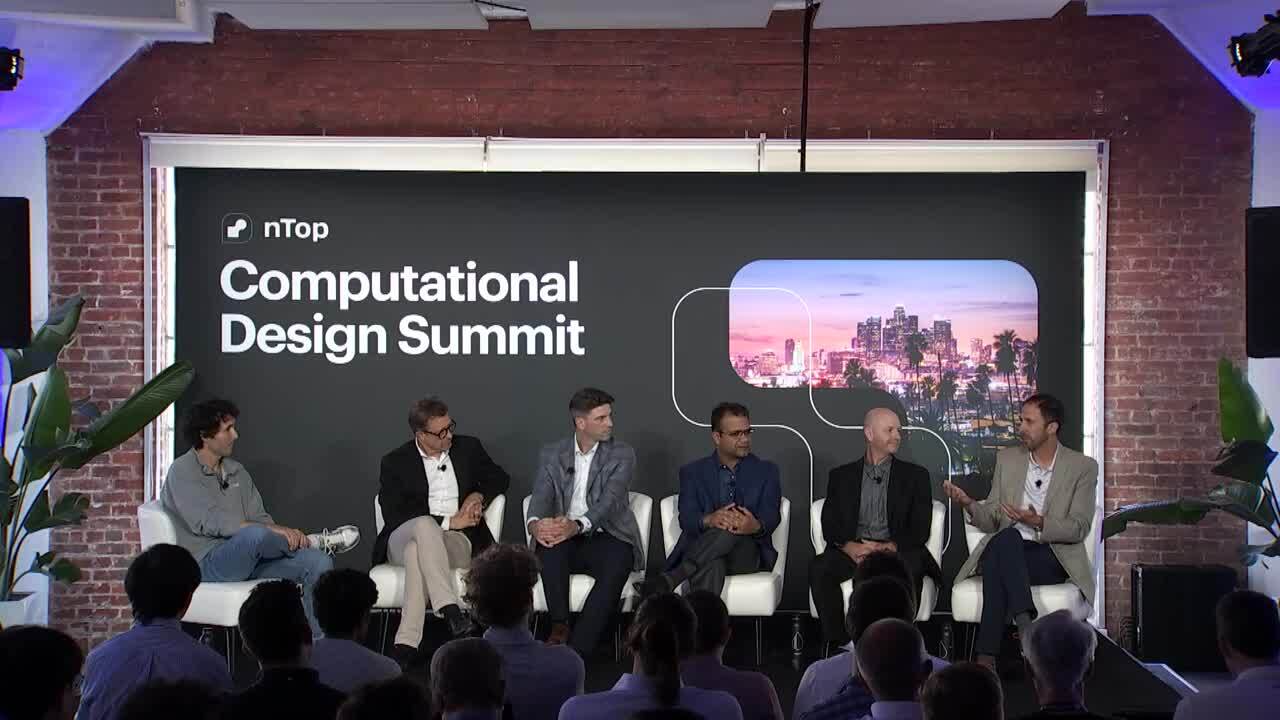

nTop CDS 2024: How leading companies are embracing computational design

- VIDEO

nTop CDS 2024: Exploring the cutting edge of computational design with Matthew Shomper