Tooling design

Save time, cut costs, and improve tooling performance with nTop’s advanced design automation capabilities for additive manufacturing (AM).

Objectives of tooling design

Tooling with AM creates opportunities for engineers to increase throughput, reduce design time, and save costs.

Industry applications of tooling design

Additive manufacturing enables engineers to create advanced tooling across various applications.

Molds and dies

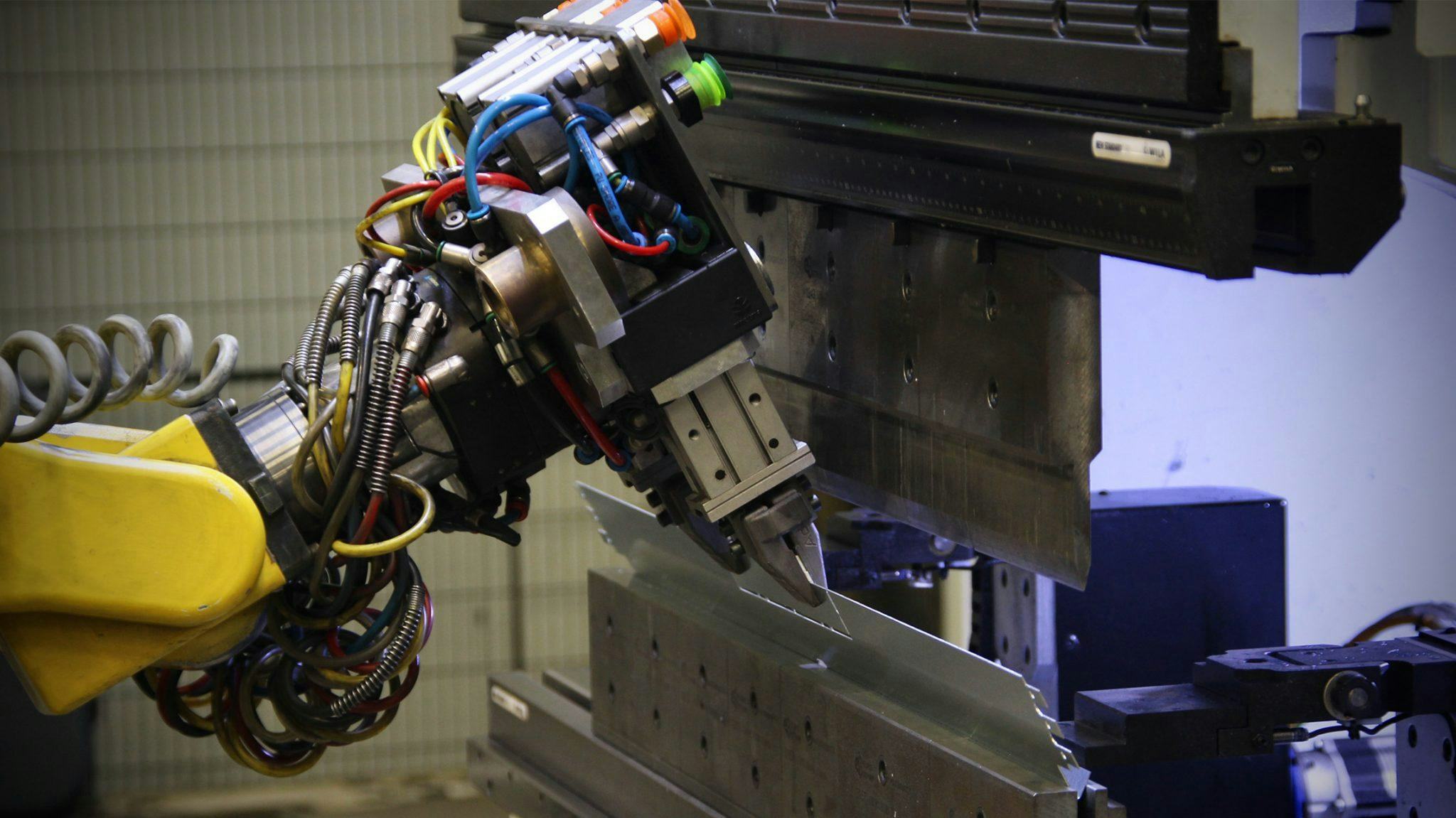

Additive manufacturing allows engineers to create more efficient parts, molds, and dies with new functionalities, like internal channels and conformal perforations. With AM, engineers can save time and money by rapidly iterating to optimize tool design and consolidating tooling assemblies.

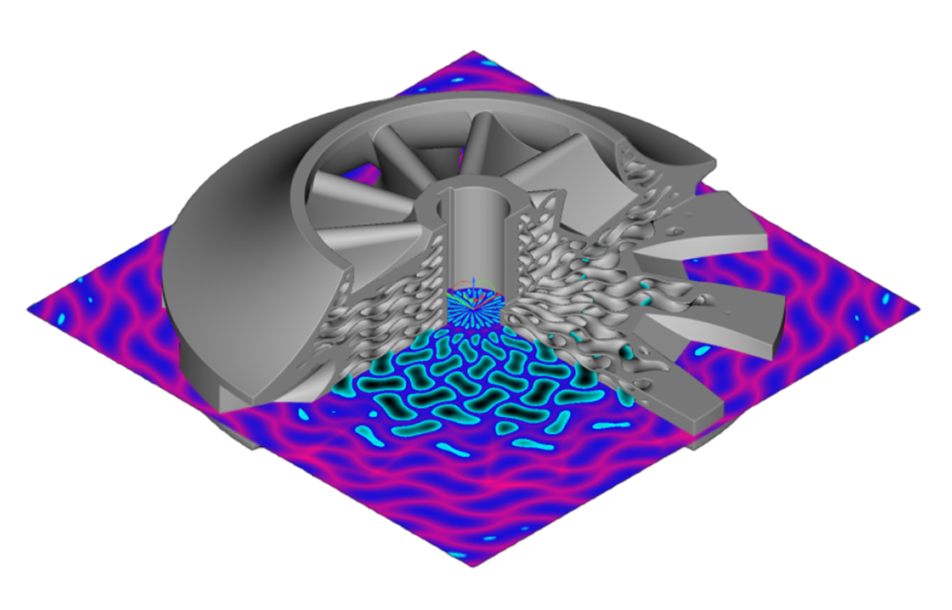

Conformal cooling

With additive manufacturing, engineers can design better performing molds and dies with complex cooling channels or perforations that were previously impossible with traditional manufacturing. Cooling channels can help extend tooling life while reducing production cycle times.

Jigs and fixtures

Additive manufacturing enables engineers to create custom jigs, fixtures, drill guides, masks, stilts, and setters to minimize manufacturing time and cost.

nTop's key Tooling Design capabilities for additive manufacturing

Design automation

Encode your expertise in a block-based visual programming environment, and scale your design process with scripting.

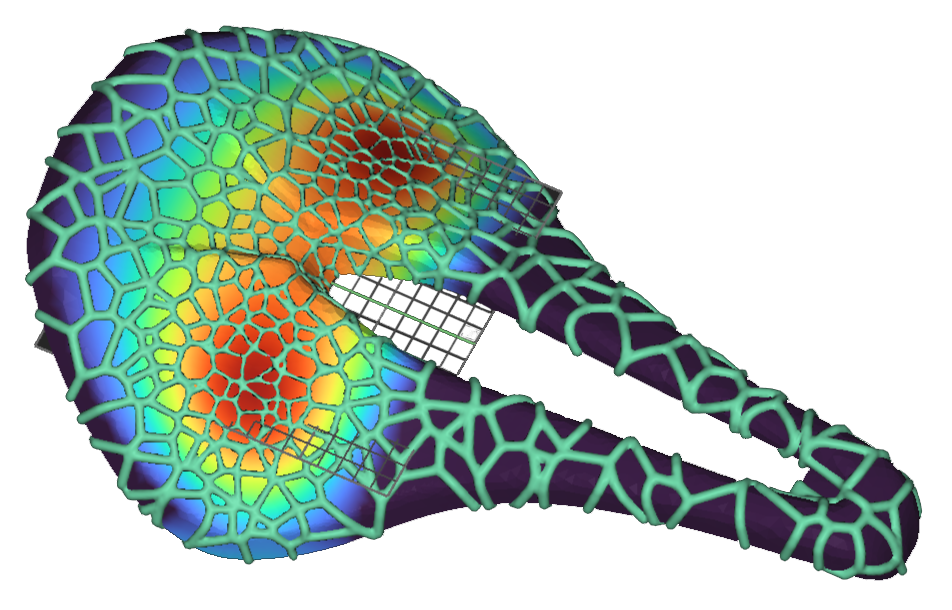

Perforations

Generate perforation patterns with thousands of elements on the surface of any part. Control the hole shape, size, spacing, and direction.

Advanced modeling

Perform reliable boolean and shelling operations. Create robust designs with smooth blends, fillets, rounds, and walls of variable thickness.

Build preparation

Create automated build preparation processes for additive manufacturing and ensure your designs are ready for production.

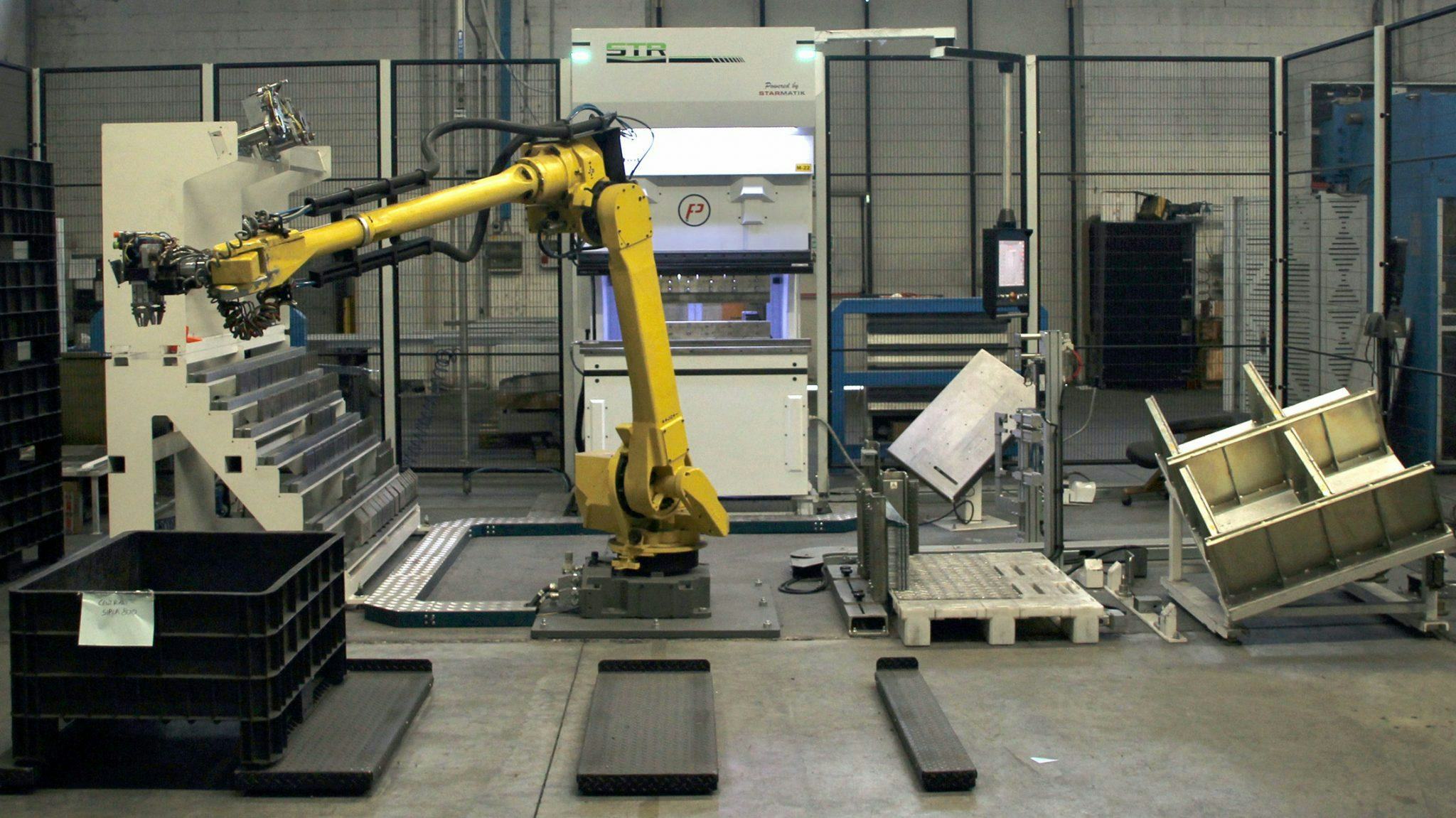

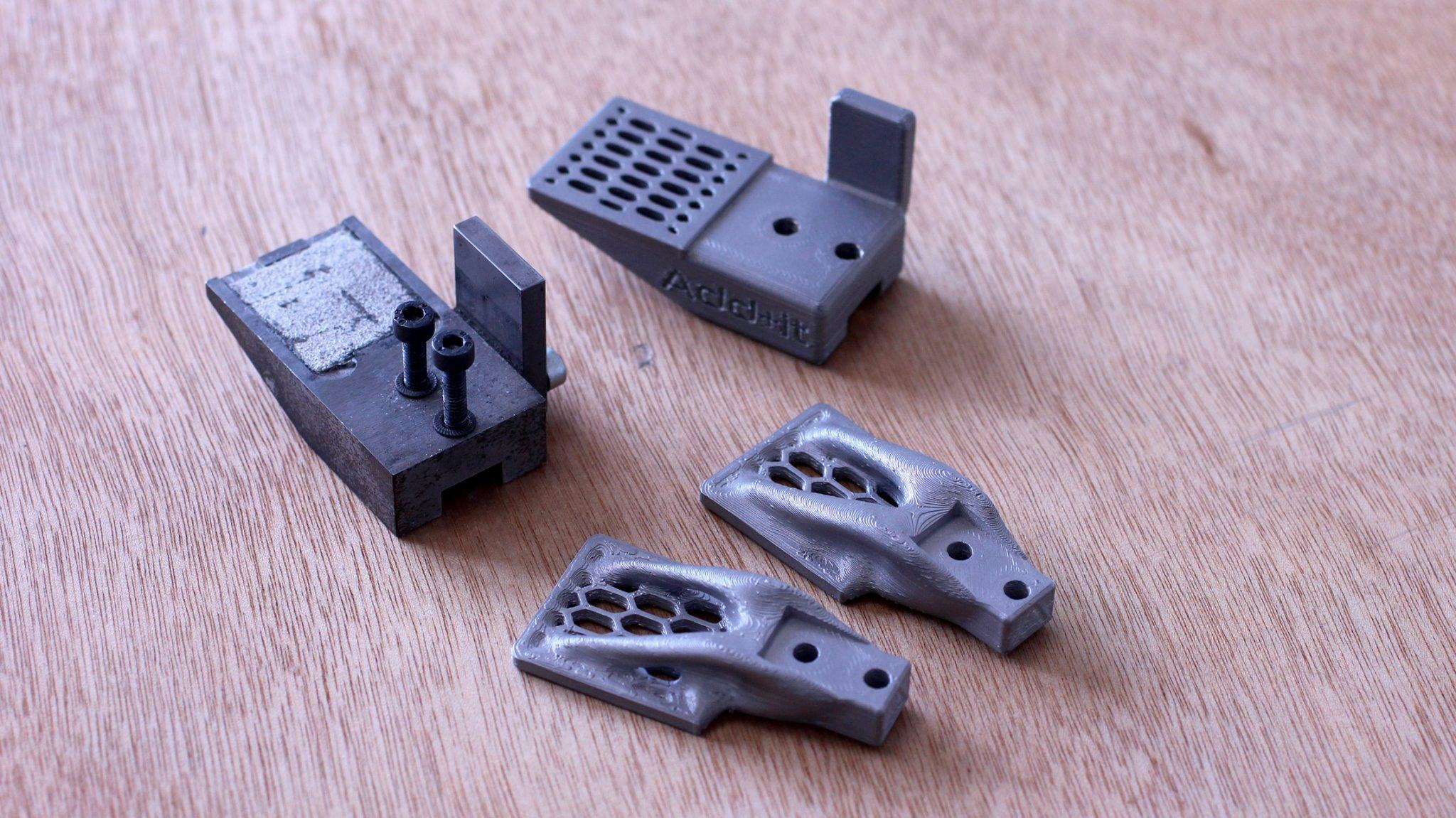

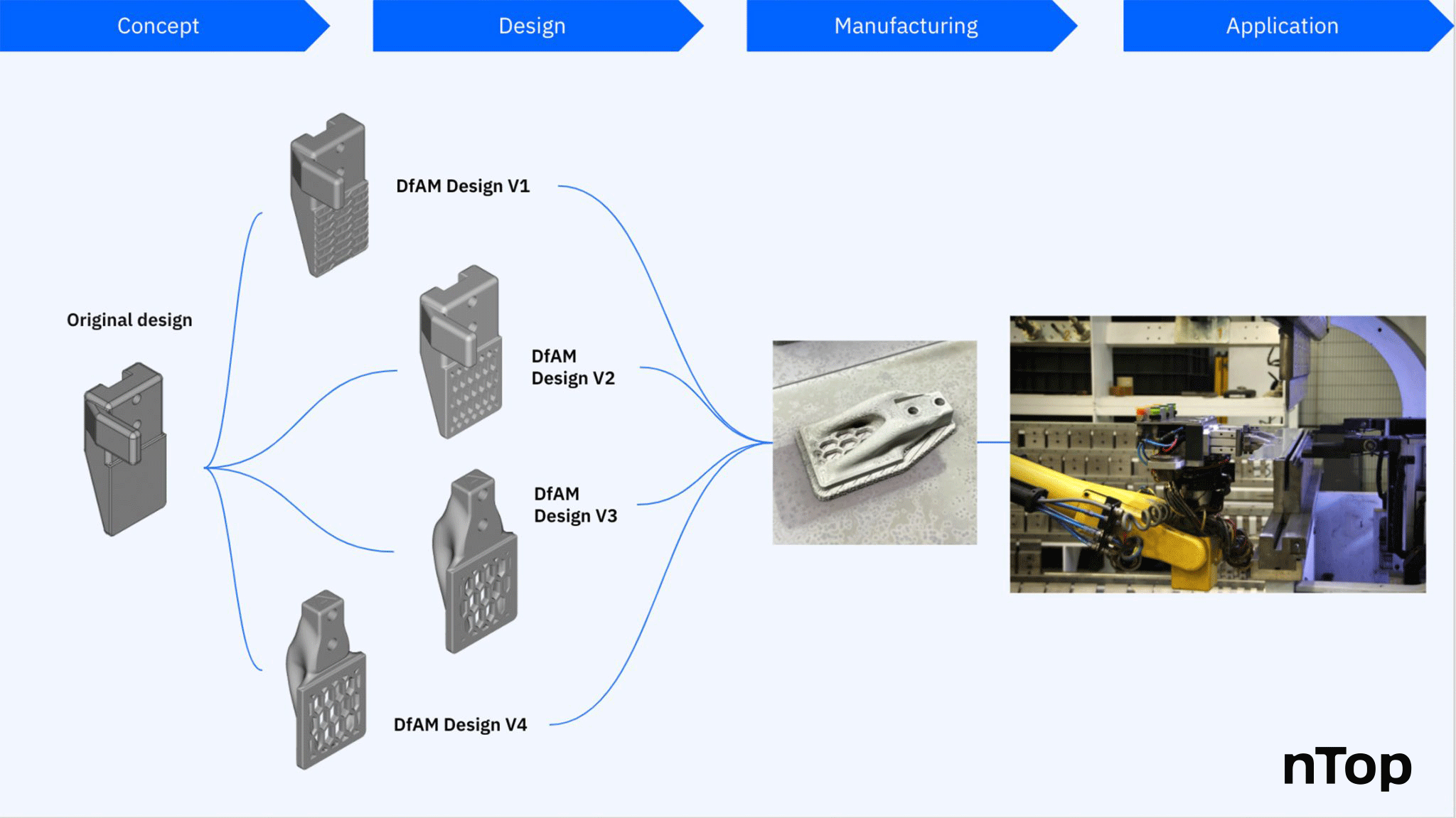

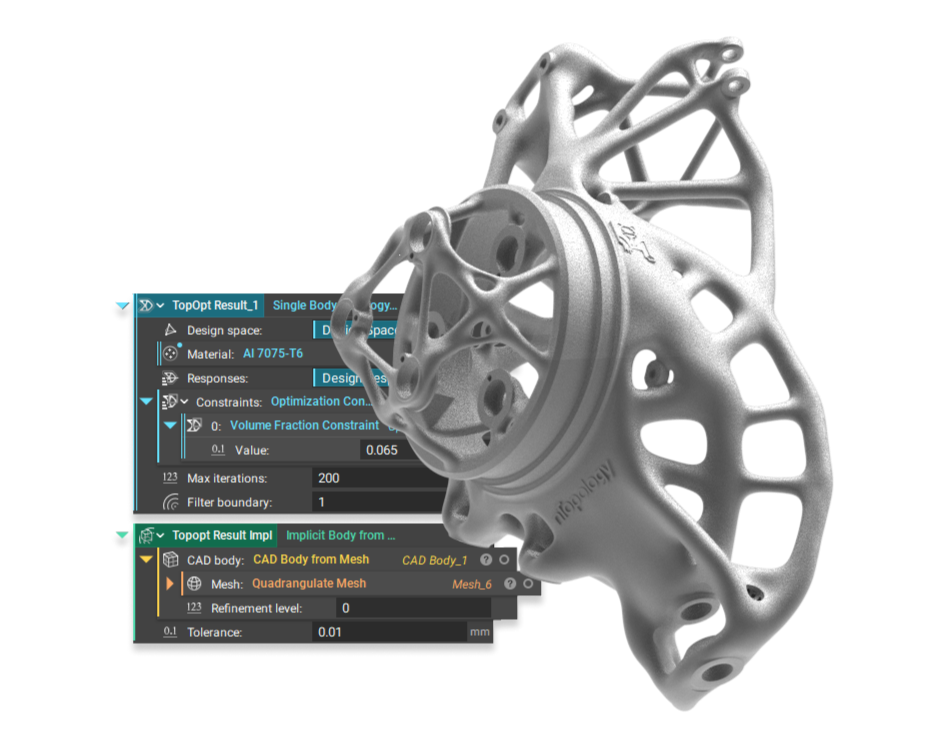

Creating 3D-printed robot grippers in just four days with topology optimization and reusable workflows

Preziosa Francesco and Add-it created custom 3D-printed metal robot grippers to bypass long CNC lead times. In the process, they created a topology-optimized fixture that enables lights-out manufacturing while reducing weight and saving cost.

Software built on transformative technology

Tooling design resources for engineers and designers

- VIDEO

Automated design of hole drilling patterns for complex molds

- WEBINAR

Easy tooling design for 3D printing: Overcome the CAD hurdle

- VIDEO

Designing 3D printed molds for industrial injection molding

- ARTICLE

Design brief: 3D printed casting of 3-foot long robot arm

- VIDEO

Rapid design of thermoforming molds for clamshell packaging

See how you can improve tooling performance.

nTop helps you maximize the benefits of AM.