Design lighter, better-performing parts.

Why choose nTop for lightweighting?

nTop’s lightweighting tools can help you achieve design objectives that aren’t possible with CAD alone. By adding nTop to your existing workflows, you can unlock tangible, high-impact results.

nTop’s critical tools for lightweighting with additive manufacturing

nTop features four powerful tools to help you design parts that are lighter, more efficient, and more precise.

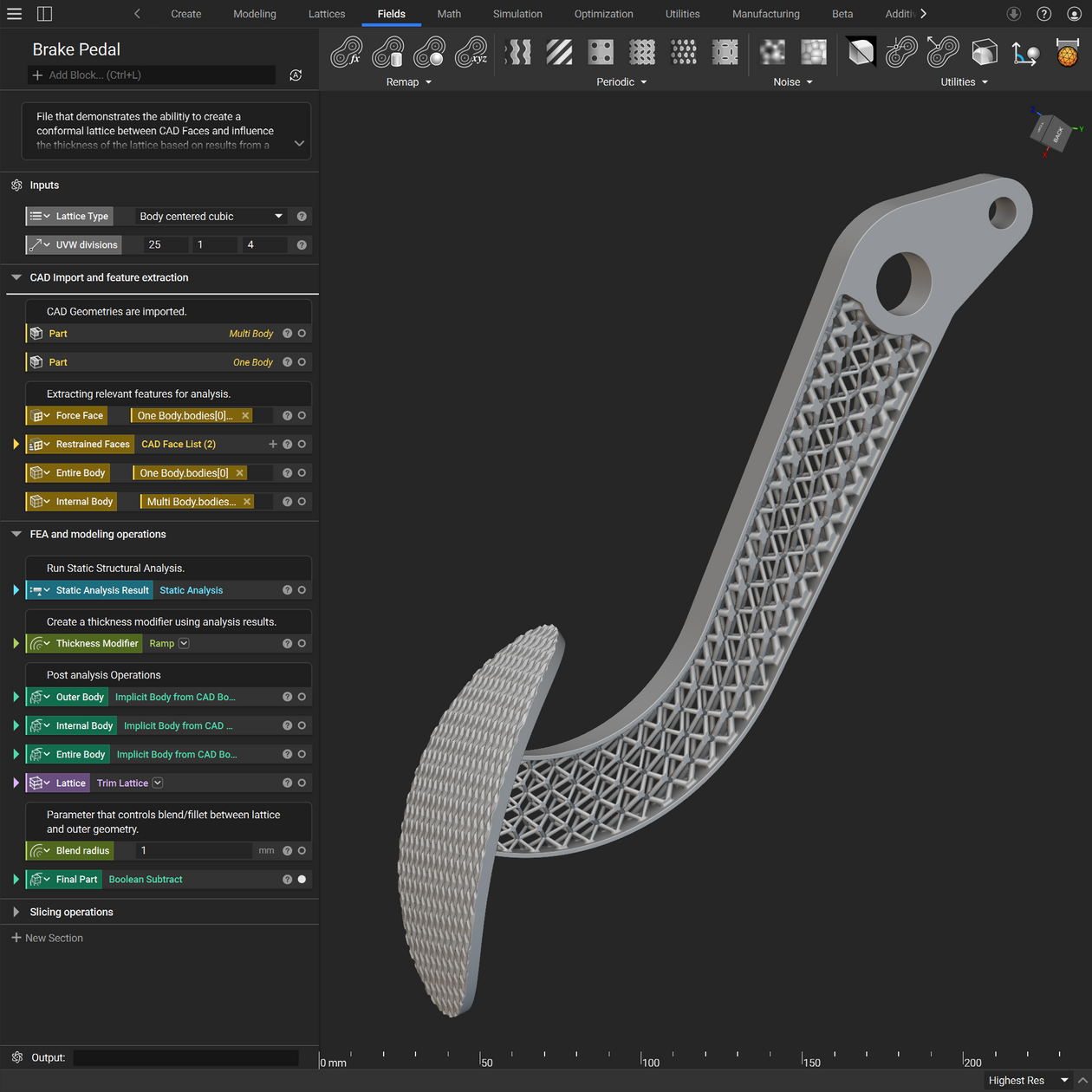

Lattice structures

Generate complex, scalable lattice structures, with variable thickness and smooth transitions, in seconds.

Topology optimization

Drastically reduce material cost and design time with automated topology optimization and post-processing workflows.

Variable shelling

Reduce weight with variable shelling, where shell thicknesses can be driven by data, such as simulation results, for optimized designs.

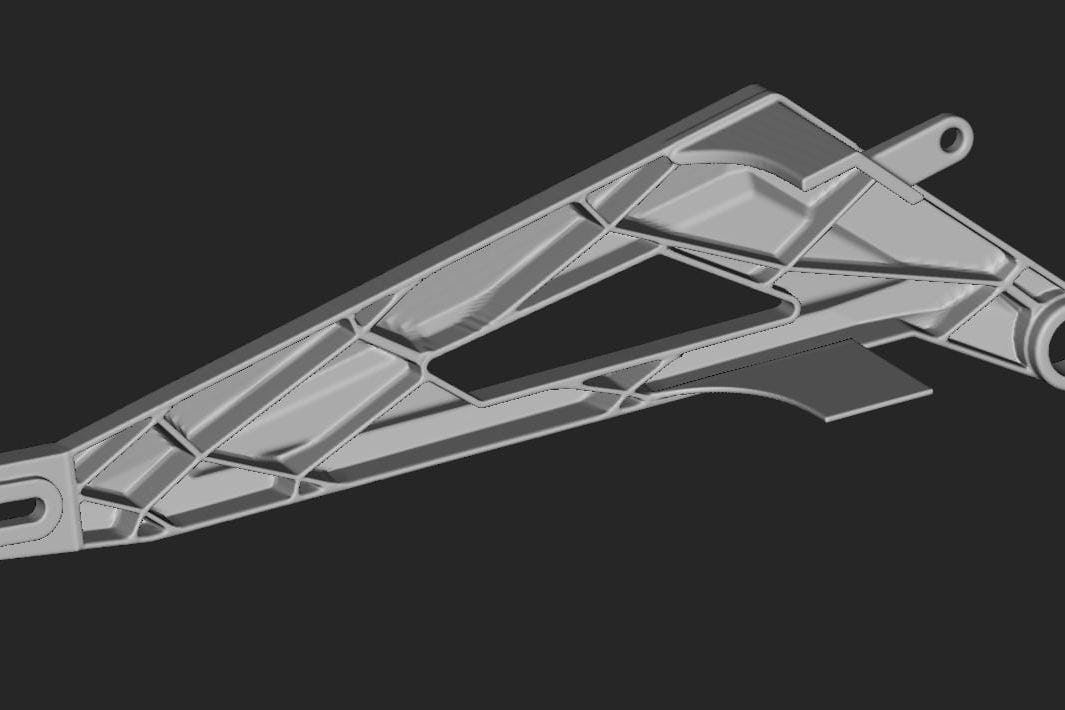

Conformal ribbing

Use ribbing to conform to any complex surface, enabling thinner walls without sacrificing structural integrity.

Get our lightweighting guide.

Topology optimization and reusable workflows create lighter, more precise robotic end-effector

The engineers of DMG MORI’s ADDITIVE INTELLIGENCE team redesigned their Robo2Go head for additive manufacturing using nTop. The new design is 62% lighter, has 60% fewer components, and improves the handling precision of the robot by a factor of 16x.

Lightweighting resources for engineers and designers

- VIDEO

Topology optimization driven ribs on a swing arm

- ARTICLE

Automotive lightweighting: Achieving radical gains through design

- ARTICLE

Structural optimization: 7 design tips for lighter designs

- ARTICLE

Lightweighting applications through smart engineering design

- ARTICLE

8 benefits of lightweighting in manufacturing and engineering

See what lightweighting can do for your parts.

nTop has the tools you need to get lighter, more efficient parts to market fast.